Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.37 Valve electric drive of machine motor-in-wheels

Developers’ contact information

State Scientific Institution “Joint Institute of Mechanical

Engineering of the National Academy of Sciences of Belarus”

12, Akademicheskaya Str., Minsk 220072

Tel/fax: +375 (17) 210-07-49; Web-site:

http://oim.by

Vladimir Iosifovich Adashkevich

Tel.: +375 (17) 284-03-65

Summary

“Valve electric drive of machine motor-in-wheels” is a

constructively completed driving of motorized wheel type comprising:

three-phase AC electronic motor with excitation from permanent-magnets

integrated into hub design of motorized wheel according to direct-drive scheme

and special-purpose controller that provides control over AC electronic motor

and implementation of machine traction characteristics. The mode setting

movement of the valve electric drive is carried out from the general electrical

integrated control system of the mobile machine through standard communications

channel or from a free-standing unit. The electric drive with the capacity of

up to 10 kW is designed for use in small-sized various-purpose means of

transport (ecologically safe transport for leisure areas, industrial

inshop-floor travelers, etc.) and as base components of mobile machines of

hybrid type and machine with new power generating systems..

Description

The production of ecologically cleaner and more energy efficient

land-based vehicles is the top-priority task of the leading world automakers.

The automobile companies: General Motors, Toyota, Honda, Daimler-Chrysler, etc.

have conceptual engineering designs or finished models of electrically driven

cars, hybrid cars or cars with alternative power generating systems. One of the

most important components of the above mentioned cars is their mover made in

the form of a motorized wheel with direct electric drive.

The electric drive on the basis of ac electronic motor energized from constant

magnets made from rare-earth metals is advanced drive type for means of

transport, including its usage in motorized wheels. Its application makes it

possible to get high dynamic indexes, good overload capability, wide range of

regulation. This type of engines has the best weight-power ratio in comparison

with other electric motors.

| DC motor |

12,7 kg/kW |

| asynchronous motor |

8,8 kg/kW |

| AC electronic motor |

5,2 kg/kW |

The high-torque characteristics of AC electronic motor make it possible to use

it as a direct drive in motorized wheels.

Upon generation of an electric directly driven valve for motorized wheels of

mobile machines, the following basic objectives have been set:

- The construction design of motorized wheel with inbuilt

3-phase valve eddy current motor is worked out, it was accommodated to the

understructure of small size means of transport;

- The hardware and software components of a special-purpose

controller of electric motorized wheel valve drive is worked out that

carries out modes of motion and traction characteristics of the mobile

machine;

- The techniques of motorized wheel characterization have been

worked out. These techniques of characterization are carried out due to

computer and full-scale modeling at the stages of development and testing

of drives of different capacities and applications. A test stand for

electric motorized wheel drive has been produced.

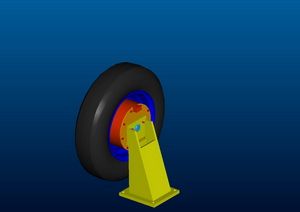

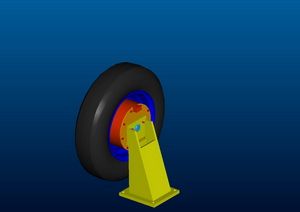

- Fig. 1-2 show functional parts of the directly-acting

electric drive for motorized wheels of mobile machine.

Fig. 1 – Motorized wheel (tire R13) with electronic AC

motor type RSM-24, 3 kW

It is meant for setting in small-sized means of transport on the understructure

and is equipped with support hook for carrying out of benchmark tests.

Fig. 2. The baseplate of a special-purpose controller of

electric valve drive of a motorized wheel

It is made on the basis of a microprocessor sequencer C8051F3XX produced by

Silicon Laboratories and of application-specific integrated circuits type

IR2214SS - power bridges IGBT drivers. It makes it possible to programmatically

change the control parameters of AC electronic motor.

Table 1 shows global parameters and characteristics of electric valve drive of

a motorized wheel.

Table 1

Parameter or characteristics

(electric RSM 24 motor with convective cooling - special-purpose

controller) |

Value |

| 1. Long-term (rated) rotational moment,

Nm |

97,0 |

| 2. Peak torque, Nm |

260,0 |

| 3. Motor torque at full-load torque (winding

temperature up to 120 &geg;C), A |

16,9 |

| 4. Motor current at peak torque (winding

temperature up to 120 &geg;C), A |

44.0 |

| 5. Maximum rotations per minute, rpm |

550 |

| 6. Nominal power on axle tree, kW |

3,7 |

| 7. DC pull up voltage, V |

310-600 |

| 8. Motor dimensions, mm |

D=240; H=115 |

The calculation of power parameters that are necessary for movement of small

sized transport with the weight of 600 kg at a high speed of 30 km/h shows that

the above mentioned direct valve actuator consisting of two motorized wheels

provides this mode of movement.

Technical and economic benefits:

This engineering design is in the tideway of producing of environmental

responsible and energy efficient land-based vehicles. Powerful rare-earth

magnet production and progress in power electronics provide conditions for wide

use of valve high-torque motors. The drive system of motorized wheel type has a

lot of advantages. Motor in-building in each wheel reduces general power demand

of internal combustion engine of a hybrid mobile machine. This electric drive

provides new possibilities for yaw controls, antispin system, antiskidding

system, etc. Ac electronic motor produces high starting moment already at low

rounds that is why machine running-away performance increases by far.

Present-day developments in the area of power and microprocessor technology

provided conditions for electric valve drive application of a new generation on

the basis of synchronous motors with constant magnets for most various

applications; including mobile machines. Cost parameters for motorized wheels

on electric valve drives are a little higher than for an asynchronous motor

drive with gear system. However, the tendencies of depreciation of rare-earth

magnets and electronic components guarantee high competitive advantages of

directly-operating electric valve drive other types of drives.

Technology type

Technical advantages and economic benefits

—

Technology differentiation and uniqueness

This development is related to modern innovative projects.

Context in which technology was identified

The technology was generally presented at research memorandums

and at conferences held by the Joint Institute of Machine Building of the

National Academy of Sciences of Belarus. Some of publications on the project

topic are given below.

- V.V. Zharskiy, I.V. Daynyak, V.I. Adashkevich, I.V.

Temruk, M.A. Arebi. The construction of power turn drive for motorized

wheels// Ingenernyi vestnik – February 2007. – Issue 1(21)/ 5. – pp.

59-62.

- I.V. Daynyak, A.A. Agranovich, D.A. Stepanov, V.I.

Adashkevich, V.V. Zharskiy. Computer model of generalized electrical

machine.// Ingenernyi vestnik – March 2007. – Issue 1(21)/5. – pp.

125-131.

- V.V. Zharskiy, L.G. Krasnevskiy, D.A. Stepanov, I.V.

Temruk., M.A. Arebi. A generalized mathematical model of elementary

synchronous motor. // Ingenernyi vestnik – January 2007. – Issue

1(21)/5. – pp. 136-140.

Total of 21 works was published, among them 2 were published abroad.

Technological keywords

Electric valve drive, motorized wheel, means of transport,

commutatorless motor, controller, mobile machine, control system.

Development Stage

- Applied research

- Prototype

- Results of demonstration test available

Intellectual property rights

- Other:

Preparation of applications for engineering solution on the subject is

carried out.

Range of applications

Motor-and-tractor machine industry.

Classifier Used at the EU Innovation Relay Centres

- Industrial Manufacturing, Material and Transport Technologies

Preferable Regions

Practical experience

Full-scale specimen processing, modeling, experimental research.

Environmental impact

None.

Type of collaboration sought

- Other:

Agreement. Joint production.

Terms and restrictions

No right of exploitation to a third person.

Available technical assistance

- Other:

Finishing of engineering solutions and documentation before prototype

stage.