Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.36 High-porous cellular material based on nickel and

aluminium-oxide ceramics

Developers’ contact information

State Scientific Institution “The Powder Metallurgy Institute of the National Academy of Sciences of Belarus”

41 Platonov Street, Minsk BY-220005

O.L. Smorygo

Tel.: +375 (17) 293-98-23

Summary

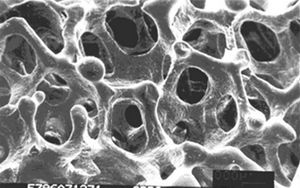

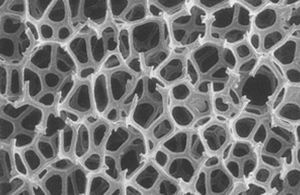

Open-cellular nonorganic foam materials are made by doubling of

foam-polymeric compound structure and have a complex curly structure consisting

of interdependent cells systems. Open-cellular nonorganic foam materials have

extremum high porosity and permeability, heat resistance, corrosion stability,

catalytic reactivity.

Description

At present foamed metal and cellular ceramic production

technologies have been worked out on the basis of the following materials:

- Metals: Ni, Ni-Al, Ni-Cr,

Ni-Cr-Al, alloys Cu, etc..;

- Ceramics: Al2O3,

Al2O3-SiO2,

ZrO2, cordierite-mullite, mullite-zircon, etc.

- Cellular ceramics and foamed metals with protective and

catalyst active coatings: Ag, glass (glazing), γ-

Al2O3/Pd(Pt), γ-

Al2O3-La2O3,

mixed oxides, etc.

Manufactured foam materials have the following properties.

| Properties |

Foamed metal |

Cellular ceramics |

| Apparent porosity, % |

92-97 |

75-90 |

| Transverse modulus of rupture, MPa |

- |

0.5-2.0 |

| Ultimate compressive strength, MPa |

0.8-1.5 |

- |

| Operating temperatures, °C |

up to 1100 |

up to 1550 |

| Pore size, mm |

0.3-5.0 |

1.0-5.0 |

| Coefficient of permeability, m2 |

10-7-10-9 |

10-7-10-9 |

| Maximum linear dimensions, mm |

500 x 500* |

150 |

| Thickness, mm |

1-25 |

10-25 |

* in case of pure Ni

Technology type

Technical advantages and economic benefits

Advantages over analogues: wide range of materials and wide range

of thermophysical and hydrodynamic parameters.

Technology differentiation and uniqueness

The materials have unique operational characteristics in a wide

range of practical applications.

Context in which technology was identified

9-th, 10-th, 11-th International Specialized Exhibitions “Metal

powder industry - 2003, 2005, 2007”.

Technological keywords

Foamed metal, cellular ceramics, filter, block catalyst.

Development Stage

- Experimental development stage

- Results of demonstration test available

- Currently in use/production

Intellectual property rights

Range of applications

- Filtration of viscous fluid, severe or hot fluids and

gases, vapour recovery of precious metals, etc..

- Catalysis – primarily ecological one.

- Heating gas systems of radioactive type.

- Flame-arresters, e.g., in welding engineering.

- Electrodes – in batteries, trapping ion systems.

- Superlight constructional materials.

Classifier Used at the EU Innovation Relay Centres

- Industrial Manufacturing, Material and Transport Technologies

Preferable Regions

- South America

- Asia

- Africa

- Australia

Practical experience

- Catalyst carriers, ceramic foam

- are used in neutralizing tanks of burning up of effluent

gases, units of deep oxidation of hydrocarbons and other catalyst

systems as block catalyst carriers.

- are made from silicate or cordierite ceramics with finely

divided coating.

- it is possible to apply finely divided coating with

catalyst active elements (including platinum group metals).

- Catalyst carriers, foamed metal

- are used in neutralizing tanks of burning up of effluent

gases, units of deep oxidation of hydrocarbons and other catalyst

systems as block catalyst carriers.

- are made from nickel, cuprum, iron and other metals and

their alloys;

- it is possible to apply finely divided coating with

catalyst active elements (including platinum group metals).

- Ceramic foam filters

- are used as filters for fluids and gas treating, treating

of melts of metals and polymeric compounds, flame-arresters, noise

limiters, insulation kits.

- are made from aluminosilicate ceramics.

- Foam metal filters

- are used as filters for fluids and gas treating,

polymeric compounds, noise limiters, flame-arresters

- are made from nickel, cuprum, iron and other metals and

their alloys.

- Test model of low temperature catalytic combustion

unit.

Scope of application: deacidification of dangerous volatile organic compounds

that are released into the atmosphere by enterprises of various branches of

industry (in particular, emissions of ethanol and ethyl acetate mixture are

typical of printing industries). Conversion rates: more than 99% at space

velocities of gas flow (0.8-2)·104 1/hour for vapour concentration

of organic vapours of organic compounds 0.5-5 g/m3. Operating

temperature: 230 – 270 °C.

Environmental impact

None.

Type of collaboration sought

- R&D contract

- Joint venture

- Other:

Production sale;

Technology sale.

Terms and restrictions

None.

Available technical assistance