Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.27 Laser quenching technology

Developers’ contact information

State Scientific Institution “The Physical-Engineering Institute of the National Academy of Sciences of Belarus”, Metal Science Department, Laboratory

for Microcrystalline and Amorphous Materials

10 Academician V.F.Kuprevich Street, Minsk BY-220141

Summary

Laser thermal treatment technology is based on the use of heat generated on metal surfaces when absorbing laser beams

Description

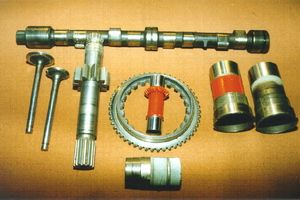

This laser quenching technology can be applied for a wide range

of parts. The State Scientific Institution “Physics and Technology Institute

of the Academy of Sciences of Belarus”, for instance, developed a laser

hardening technology for suspension components (brackets, lug) of MAZ 6422 rear

axle to prolong their service life by 3 times. What concerns “shaft-sleeve”

type parts (Borisov plant “Avtohydrousilitel”), the value of operational

necks hardness achieved is 60 HRC units with total part hardness of 40 HRC

units, and etc.

Great prospects are opening for laser quenching in tool-building industry.

Thus, quenching of cutting and cold heading tools, press and stamping

accessories increases their durability by 3-5 times and more. The technology

was tested at BelOMO, “Motovelo”, OJSC, Heavy stamps forging plant, Borisov

plant “Avtohydrousilitel”, and etc. The 1.6–3.0 increase effect was

observed for metal and wood cutting tools, including those with cartridges.

The Institute developed an alloy building process for forging dies involving

5XHM steel, which gives a durability gain by 3-4 times. Laser alloy-building

method provides for obtaining 68-70 HRC units layers on steel and titanium

alloys and 25-30 HRC units layers on aluminium alloys. The method proves to be

efficient with such parts as fodder chopper cutting blades (Production

Association “Gomselmash”), tunneling machine cutters (Production

Association “Belaruskaliy”), and etc.

Technology type

Technical advantages and economic benefits

This laser treatment method has a number of advantages: improved quenching local properties (which provides for significant saving), no need to use cooling mediums, a possibility to apply this method as a finishing operation due to contraction risk absence, comprehensive prospects for process automation, and etc.

Technology differentiation and uniqueness

—

Context in which technology was identified

Russia.

Technological keywords

Laser quenching, alloy-building, parts, stamps.

Development Stage

Intellectual property rights

Range of applications

Manufacturing engineering, tool-building industry.

Classifier Used at the EU Innovation Relay Centres

Preferable Regions

Practical experience

The technology is introduced at a number of Belarusian enterprises.

Environmental impact

None.

Type of collaboration sought

Terms and restrictions

—

Available technical assistance