Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.17 Development of accessory cushioning system for special purpose heavy-weight truck (tractive vehicles) elements

Developers’ contact information

1) State Scientific Institution “The A.V.Lykov Institute of Heat and Mass Transfer of National Academy of Sciences of Belarus”

15 P.Brovka Street, Minsk BY-220072

Tel.: +375 (17) 284-21-38, fax: +375 (17) 292-25-13

Summary

The project is devoted to development, research and testing of

controlled accessory cushioning system for heavy-weight truck elements which is

based on rheological dispersities.

The cushioning system consists of a slave mechanism which is a viscous friction

shock damper with electro-driven (or magnet-driven) operating environment. Its

damping characteristics change exponentially on switching to external control

mode. The cushioning system also includes standard elastic elements and a

control unit complete with a vibration transmitter. The system is intended for

adaptive anti-vibration modes control initiated on transportation of

high-precision cargoes and can be used to provide appropriate operational

conditions both in motion and stationary functioning modes.

Specifications:

Description

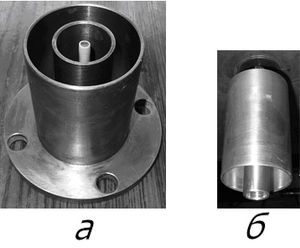

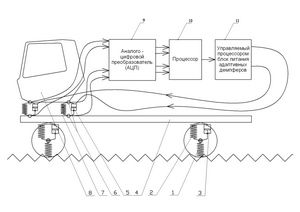

The project is aimed at constructing a test model of an active anti-vibration system for heavy-weight vehicles elements based on the principle of anti-vibration device inertia and stiffness parameter control with viscous friction dampers used as actuator units. The system implements an efficient coupling method for hydraulic and electrical components implying elimination of kinematical connections which is achieved by electrostatic field direct impact on the damping unit operating liquid. The project resulted in the development of controlled parameters electrorheological compounds (damper operating liquids), procedures and hardware for automated vibration control systems of dynamically loaded elements, vehicle units and working stations (shock damper with electrorheological operating liquid (Fig. 1) and electronic control unit), which served as a basis for adaptive accessory cushioning system design (Figure 2).

Fig. 1 – Electrorheological shock damper appearance

a – bottom; b – top

Fig. 2 – Adaptive accessory cushioning system block diagram

Highly-qualified originating team has enough necessary research and practical

experience and is composed of employees working for the Heat and Mass Exchange

Institute named after A.V. Lykov of the National Academy of Sciences of Belarus

(major CIS institution specializing in this problem). Based on its long

experience in the sphere of non-linear viscoelastic liquids with the use of

available material and research resources, the Institute carried out studies to

determine electrorheological liquid physical properties, developed most

effective purpose-specific compounds, helped elaborate measurement methods and

media to define their structure control algorithms involving external fields

influences. The originating team also included employees of Associated

Institute of Manufacturing Engineering at the National Academy of Sciences of

Belarus who contributed to an adequate design of electronic system control

unit. The unitary Enterprise “Minsk Wheel Tractor Plant” (this is the end

user organization and its financial investments from its proper funds amounted

to 50% of the project cost) with the participation of the Heat and Mass

Exchange Institute named after A.V. Lykov at the National Academy of Sciences

of Belarus manufactured a shock damper, tested and examined anti-vibration

system elements on an available factory stand equipped with a standard

instrumentation set and validated the declared accessory cushioning system

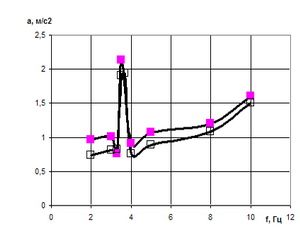

parameters. Examples comparing amplitude-frequency features are illustrated on

Figure 3..

Fig. 3 – Damping system amplitude-frequency features with control on (1) and off (2) signals

The project resulted in development and proof trial of an active anti-vibration

system for heavy-weight vehicles construction elements which seems to be quite

competitive on the market.

Technology type

Technical advantages and economic benefits

Damping ratio for the vibration system with controlled operating liquid was increased up to 5 times.

Technology differentiation and uniqueness

Application of “smart” (electrorheological liquid) materials for the purpose of constructing a controlled vibration dampening system.

Context in which technology was identified

Unitary enterprise “Minsk Wheel Tractor Plant”, Republican Unitary Enterprise “Minsk tractor factory”.

Technological keywords

Heavy-weight vehicles, anti-vibration system, cushioning system, shock damper, electrorheology, electronic control system, electrical field, process procedure, design documentation, stand tests.

Development Stage

Intellectual property rights

Range of applications

Manufacturing engineering, transport.

Classifier Used at the EU Innovation Relay Centres

Preferable Regions

Practical experience

Tests at “Minsk Wheel Tractor Plant” (Belarus).

Environmental impact

None.

Type of collaboration sought

Terms and restrictions

Licensing.

Available technical assistance