Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.13 Process development and equipment design for manufacturing hollow-bored specific-length work pieces from various cast irons by the method of wall molding in cycle-continuous casting mode

Developers’ contact information

State Scientific Institution “The Institute Of Metal Technology of the National Academy of Sciences of Belarus”

11 Byalynitskaga-Biruli Street, Mogilyov BY-212030, Republic of Belarus

Summary

A crucially new casting process and equipment employed to realize

it provide for obtaining coreless hollow-bore cylinder work pieces exhibiting

the output rate of 100-240 castings/h. The technology ensures improved

mechanical and performance properties of casting material.

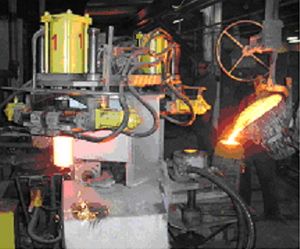

Fig. 1 – The process plant for cycle-continuous casting.

Description

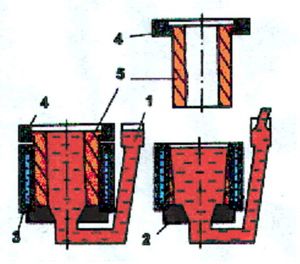

Fig. 2 - cycle-continuous dip-forming process: 1 - metal duct; 2 - connection nozzle; 3 - fixed molding unit; 4 - movable molding unit; 5 - casting

The developed method is based on the principle of ensuring proper conditions

for directional solidification. Its essence is as shown on Figure 2. Liquid

metal is fed through a bottom gate and a connection nozzle into a water-cooled

mold consisting of a fixed and a movable section. Feeding continues till the

appropriate casting height is reached. Then metal feeding is suspended to

provide for molding a work piece wall of appropriate thickness. After skin

making up the casting body solidifies it is drawn up from the fixed mold and

metal bath with the help of gripping tools. Simultaneously, a new portion of

liquid metal equal to the volume of the previous casting is fed into the mold.

The cycle is reproduced. Thus, the casting process is effected in a

cycle-continuous mode. The molding procedure is accompanied by intensive radial

heat removal and abundant feeding of the solidification front with liquid phase

over the entire solidification period. This eliminates shrinkage and gas

porosity, presence of non-metallic and cinder inclusions in the casting body

and ensures a high-dispersion structure, improved density and hardness of

work-pieces. Absence of any core provides for free shrink-off both during

casting solidification period and its subsequent cooling following extraction

from the molding form, which helps to avoid pull cracks and microfissures. The

technology allows due control of the cooling process to obtain required

structure.

Technology type

Technical advantages and economic benefits

The developed technology helps save resources and energy since heat treatment employs only primary casting heat without any external power sources. Besides, it provides for a more effective use of waste materials resulting from casting process and mechanical treatment.

Technology differentiation and uniqueness

The technology ensures crucially new conditions for hollow-bore work pieces molding which presupposes directional solidification accompanied by intensive one-side radial heat removal and constant overheating of the metal bath at the solidification front.

Context in which technology was identified

the XIIIth International Congress and Exhibition "HIGH TECHNOLOGIES, INNNOVATIONS, INVESTMENTS"; Saint-Petersburg, March 11-14, 2008; the VIIIth Moscow International Salon of Innovations and Investments, Moscow, All-Russia Exhibition Centre, March 3-6, 2008; the 11th International Symposium "Technologies, Equipment, Quality", Minsk, May 13-16, 2008.

Technological keywords

Directional solidification, freezing-out, one-side heat removal, mold.

Development Stage

Intellectual property rights

Range of applications

Foundry operation - manufacturing work pieces for high-duty parts used in manufacturing engineering, metallurgy, automobile and tractor industry, construction and etc.

Classifier Used at the EU Innovation Relay Centres

Preferable Regions

Practical experience

The technology is implemented to produce high-duty application parts of grey, high-strength and white cast iron having improved performance properties and operational resources: cylinder liners, piston and sealing rings, valve seats, punch stamps for pressers manufacturing cellular lime brick, braking cable machine disks for wire cable production, multi-purpose bushuings.

Environmental impact

None.

Type of collaboration sought

Terms and restrictions

Transfer of information to third parties without previous agreement is not allowable.

Available technical assistance