Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.11 Jet mold and a spray flooded secondary cooling system device for continuous and cycle continuous casting

Developers’ contact information

State Scientific Institution “The Institute Of Metal Technology of the National Academy of Sciences of Belarus”

11 Byalynitskaga-Biruli Street, Mogilyov BY-212030, Republic of Belarus

Summary

The devices provide for a 2-5 time increase in ingot casting procedure output and allow reducing the ingot structure by 4-10 times as compared to the casting procedure with a conventional (slit type) mold. High-speed molding makes it possible to obtain ingots of high-dispersion microstructure without any environmentally unfriendly and expensive modificators. They are used for manufacturing ingots with improved mechanical qualities and processing metal scrap to get raw stock for engineering parts.

Description

The operation of a jet mold and a spray flooded secondary cooling

system device is based on uniform height and perimeter flood and spray cooling

of mold jacket and ingot. Cooler sprays impacting cooled surface at right or

any other specific angles significantly reduce thermal border-layer thickness

at its closest proximity, which results in an increased heat-transfer factor

and an improved cooling capacity for the spray flooding procedure. Uniformity

of mold jacket and ingot cooling provides for a better durability of equipment

and casting procedure stability and improves the quality of continuously cast

ingot.

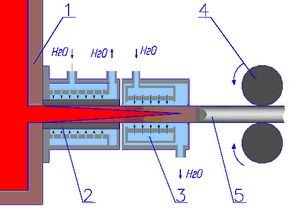

Fig. 1 – Diagram for continuous ingot casting in jet mold

with spray-flooded secondary cooling system:

1 – metal reservoir; 2 – spray mould;

3 – spray-flooded secondary cooling device for ingot;

4 – withdrawal unit; 5 – ingot

Technology type

Technical advantages and economic benefits

A considerable improvement in continuous casting output. A better quality of ingot, improved mold tube durability, increase in the recovery rates and reduction of casting manufacturing cost.

Technology differentiation and uniqueness

The innovative component is presented by a crucially new and effective spray-flooded cooling system of the mold and the ingot cooling device which provides for a significant increase in casting procedure output and an improvement in quality of ingots manufactured of various metals and alloys without having to increase cooling flow rate.

Context in which technology was identified

the VIIIth Moscow International Salon of Innovations and Investments in 2008 (awarded with a gold medal) and Petersburg International Congress “High Technologies. Innovations. Investments” in 2008 (awarded with a silver medal).

Technological keywords

Jet mold, spray-flooded cooling system, secondary cooling, ingot, continuous casting, cycle-continuous casting, alloys.

Development Stage

Intellectual property rights

Range of applications

Foundry operation, metallurgy.

Classifier Used at the EU Innovation Relay Centres

Preferable Regions

Practical experience

Provides for a 4-6 time increase in silumin output and obtaining ingots of high dispersion structure without any modificator additives.

Environmental impact

None.

Type of collaboration sought

Terms and restrictions

According to the contract.

Available technical assistance