Main Sector of relevance\IRC classification 8. Industrial Manufacturing, Material and Transport Technologies

8.10 Nano-structure eutectic Si aluminium-silicon alloys

Developers’ contact information

State Scientific Institution “The Institute Of Metal Technology of the National Academy of Sciences of Belarus”

11 Byalynitskaga-Biruli Street, Mogilyov BY-212030, Republic of Belarus

Summary

Stock of nano-structure eutectic Si aluminium-silicon alloys have an inverted microstructure and show an abnormally high ductility and enduring quality under friction. These are anti-frictional deformable alloys with improved mechanical properties.

Description

State Scientific Institution “Institute of Metallurgic

Technologies of the National Academy of Sciences of Belarus” developed a

technology allowing to obtain castings of 40-150 mm in diameter and up to 300

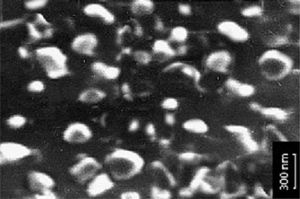

mm high using nano-structure eutectic Si silumins. The new technology is based

on hardening solidification casting method. The eutectic silicon in the

resulting castings is characterized by a globular form and a dispersion of 200

nm. At the same time the mechanical properties of prototype stock were found to

have increased by 40-70% as compared to identical prototypes which were

obtained with the use of the conventional modificator implementing technology.

Nano-structure eutectic Si silumins AK12 and AK18 under conditions of dry

friction on a steel plate exhibited a better enduring quality exceeding that of

anti-frictional bronze more than 30 times.

In addition, it was found that 20% of nano-structure eutectic Si castings added

to a fusion mixture make it possible to retain the modified structure heredity

of the stock for more than 2 hours.

The new technology of nano-structure Si hypereutectic aluminium-silicon alloy

was applied in manufacturing worm gearbox wheels and internal combustion engine

pistons. The results of tests showed a 3-time increase of prototype piston

operational resources as compared to the products manufactured with the use of

the conventional technology. The resource of prototype worm gear wheels mounted

on grinding-and-polishing machine gearboxes was 6 times more than that of

identical bronze BrAZh9-4 products.

Nano-structure Si silumin AK6-AK12 castings have an abnormal ductility,

that’s why they can be put to stamping in order to obtain multi-purpose

bushings.

Technology type

Technical advantages and economic benefits

A considerable improvement of mechanical and anti-frictional properties for silumin stock. A possibility to replace expensive and heavy-weight bronze and steel parts for identical nano-structure eutectic Si silumin products which are cheaper and lighter. A significant increase in operational resources for internal combustion engine pistons.

Technology differentiation and uniqueness

The innovative component is presented by the new inverted silumin nano-structure. It accounts for the abnormal ductility and high enduring qualities under friction.

Context in which technology was identified

Petersburg exhibition HI-TECH in 2007 (awarded with a silver medal), the IXth International Scientific and Technological Heat-treaters and Metallographers Congress in Kharkov (Ukraine), the VIIth International Scientific and Technological Symposium in Samara (Russia) in 2008 and at BelOliM international scientific and technological conference in 2006-2008.

Technological keywords

Silumin, nano-structure eutectic silicon, anti-friction qualities, hardening solidification casting, internal combustion engine pistons, stamping, ductility.

Development Stage

Intellectual property rights

Range of applications

Manufacturing engineering, instrument-making and aerospace industry.

Classifier Used at the EU Innovation Relay Centres

Preferable Regions

Practical experience

Nano-structure eutectic Si silumins are used to manufacture and supply the RUE “Zavod Optic” (Lida) with work pieces of worm gear wheels for grinding-and-polishing machines. The operational resource for the wheels is 6 times longer than that of identical parts made of bronze BrAZh9-4.

Environmental impact

None

Type of collaboration sought

Terms and restrictions

According to the contract.

Available technical assistance